The Lenz Turbine: The Perfect Vertical Wind Turbine for DIY Builders

History of the Lenz Turbine

The Lenz turbine takes its name from its inventor, Edwin Lenz, a passionate advocate for renewable energy and webmaster of the Windstuffnow website. When he set out to design this wind turbine, his goal was clear: create a vertical-axis wind turbine that was not only efficient but also very easy for DIY builders to make. The idea was not to develop a complex industrial model but rather a machine that could be built with simple, inexpensive, and widely available materials.

The first prototypes appeared quickly, including a large model installed on the roof of his own home. The results were promising: good stability, easy start-up, and respectable performance even in light winds. This hands-on success caught the attention of a small community of enthusiasts who began replicating and refining the concept.

Yet the Lenz turbine is still, unfortunately, little known and rarely used today. Despite recent, more efficient variations and some experiments in urban settings or off-grid locations, it has yet to find its place in the commercial wind turbine market. It’s a puzzling paradox, considering its potential and how easy it is to build.

Concept and Operating Principle

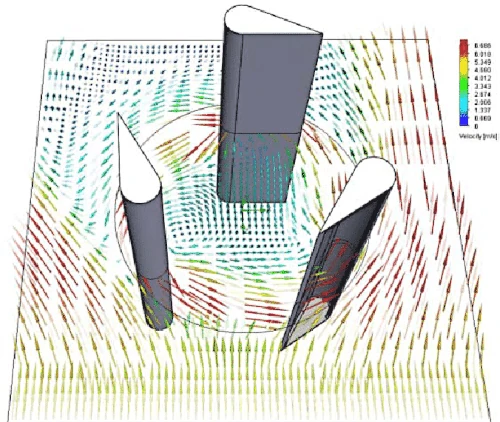

The Lenz turbine is a vertical-axis wind turbine (VAWT) whose blades, arranged around a central axis, are shaped like scoops along their entire height. The wind flows into each blade one after the other, driving continuous rotation. It’s a bit like sailing, where you adjust each sail in turn to catch as much wind as possible.

Its originality lies in its unique combination of lift and drag. It borrows from the Savonius design to capture the wind’s force through drag, while also integrating aerodynamic principles from the Darrieus turbine to take advantage of lift. This clever mix delivers high torque, ideal for applications requiring pulling power, while maintaining a moderate rotational speed. It still runs significantly faster than a classic Savonius.

Most builds use three blades, as this configuration provides good dynamic balance, reduces vibrations, and therefore lowers noise. And of course, as with all VAWTs, it allows the turbine to capture wind from any direction without the need for an orientation system.

The design is intentionally simple and forgiving of small construction inaccuracies. The most common versions are often derived from the so-called Lenz2 model, a proven concept that can efficiently transform even the faintest breeze into usable energy while still being within the reach of any motivated DIY builder.

Advantages and Unique Features of the Lenz Turbine

Once again, the Lenz turbine stands out primarily for its design simplicity. It can be built from common materials such as wood, metal, PVC, or even repurposed parts. Another advantage is that it requires no sophisticated tools. For DIY and low-tech enthusiasts, it’s a dream come true: extremely low cost and the ability to build a capable, high-performing model without complex calculations.

Its design allows it to start turning in light winds, making it an excellent choice for generating power even in moderately windy areas. You don’t need a perfect site or ideal exposure, because even the slightest breeze is enough to get the blades moving.

It delivers high torque, perfect for driving mechanical water pumps, while also benefiting from natural self-braking. This aerodynamic braking naturally limits the rotational speed and prevents dangerous overspeeding, even in very strong winds.

Its robustness makes it capable of withstanding violent winds that would damage many other turbines. Its compact design, combined with this built-in aerodynamic braking, significantly extends its lifespan compared to other models.

Another major plus is that it can be installed close to the ground, which makes inspection and maintenance much easier. And above all, it’s a forgiving design. Even with small misalignments or slight asymmetry, it will still work. Where many turbines like Darrieus or helical Savonius models demand surgical precision, the Lenz is far more tolerant. That said, this doesn’t mean you should ignore precision when building one. 😉

Power Generation and Water Pumping with a Lenz Turbine

For electricity production, the Lenz turbine offers an excellent balance between torque and rotational speed. It can spin much faster than a Savonius while still remaining slower than a horizontal-axis wind turbine. This moderate speed allows it to work with a low-RPM alternator, but to fully exploit its potential, it’s best to use a simple and effective mechanical step-up, for example a toothed belt and two pulleys to multiply the rotation speed by 2.5 or 3.

This adjustment is often enough to reach the generator’s optimal operating range and significantly improve conversion efficiency. It’s a parameter to fine-tune according to the generator’s output curve.

For water pumping, the Lenz is just as effective. Its high and consistent torque makes it a champion for directly driving a pump mechanism. All it takes is converting the rotary motion into an up-and-down reciprocating motion via a connecting rod to operate a piston. This type of handcrafted wind-powered pump can draw water from depths of 10 to 15 m (33 to 50 ft) without difficulty, even in moderate winds. The strong torque ensures reliable, constant, and smooth operation.

Bonus: To learn how to easily build your own water pump designed for a wind-powered pumping system, check out our full guide: How to Build a Water Pump for Your Wind Pumping Turbine.

Optimal Design and Proportions of a Lenz Turbine

Scoop Shape and Dimensions

The curved blades of a Lenz turbine work like scoops, catching the wind successively along their entire height. The ratio between their width and the distance from the axis determines the balance between rotational torque and rotational speed. A wide scoop produces more torque but slows down the rotation, which is ideal for water pumping applications where force takes priority.

In contrast, narrower scoops make it possible to take greater advantage of lift and effectively increase rotational speed, which is preferable for electricity generation.

Measurements from the Lenz2 design show that a scoop width of about 0.1875 × D (D being the total diameter) and a developed blade length of 0.4 × D give very good results.

To optimize energy capture even in light winds, an attack angle of around 9° is recommended.

Turbine Sizing and Power Calculation

For a Lenz turbine dedicated to electricity generation, the available power can be estimated with the following formula:

P (W) = 0.00508 × A (ft²) × v³ (mph) × η

where A = D × H is the swept area (in square feet), v is wind speed in mph, and η is the overall efficiency.

For a Lenz2, η is about 0.31, based on 75 % average generator efficiency and 41 % blade efficiency:

0.75 × 0.41 = 0.3075, which rounds to 0.31

By inverting the formula, you can calculate the area required for a given output:

A = P ÷ (0.00508 × v³ × η)

From there, the diameter is:

D = A ÷ H

Example: with P = 63 W, v = 15 mph, η = 0.31 and H = 4 ft, you get A ≈ 12 ft², which corresponds to a diameter of about 3 ft (≈ 0.91 m).

Arm Length and Geometry

The length of the arms connecting the blades to the axis directly affects efficiency. Arms that are too long place the blades too far from the axis and reduce torque. Arms that are too short cause aerodynamic interference between blades and disturb airflow.

Experience and calculations show that a good compromise is to have the anchoring radius equal to:

R ≈ (D ÷ 2) − (W ÷ 2)

This ensures good wind capture without masking effects.

Number of Blades and Performance

The number of blades determines the balance between torque and speed. Two blades produce higher speed but irregular rotation with unstable torque. Four or more blades increase torque but create excessive drag, which limits speed. Three blades are the best compromise: smooth rotation, good lift/drag efficiency, and reduced noise.

In short: fewer blades = higher speed but less torque. More blades = more torque but fewer RPM.

Blade Balancing

Even a small imbalance in blade mass causes vibrations and accelerates bearing wear. This can destabilize rotation and reduce turbine lifespan. The solution is precise balancing: check blade symmetry and weight, correct with small balancing weights if needed, and check for smooth free-spinning rotation.

The “Balourd” Effect

The balourd effect is a different phenomenon. It does not come from a blade weight imbalance but from wind pressure exerted on the top of the wind turbine. If the shaft is fixed only at its base, this lateral force causes bending and oscillation of the shaft. On a small model, fixing the blades at the center can make this problem marginal, but it is not ideal even if acceptable. On larger models, or those exposed to strong winds, the best solution is to support the shaft both at the bottom and at the top, with a thrust bearing at the bottom and a ball bearing at the top. This neutralizes the balourd effect, stabilizes rotation, and greatly extends the lifespan of the whole assembly. If the shaft is very long, adding a self-aligning ball bearing in the middle is also a good option. Too many DIY projects fail because they do not take this parameter into account, and a single strong gust can destroy a large wind turbine in just a few seconds.

Plans and Construction of a Lenz Turbine

Let’s be honest: building your own Lenz turbine is a genuinely fun project, and it’s truly exciting when you know exactly what to do and how to do it. So here’s everything you need to know to end up with an excellent model:

Hidden Content

A very important part of this how-to guide is not visible. Only members can access the full content. Registration is 100% free and takes just a few seconds. Become a member and enjoy all the services of the site. If you are already registered but still see this message, make sure you are logged in to unlock full access.

Uses of a Lenz Turbine and Practical Examples

Off-grid power generation

For those aiming for energy independence, the Lenz turbine offers a very low-cost source of renewable electricity. A small model, coupled with batteries and a charge controller, can power LED lighting, small appliances, and recharge various devices. Larger models, on a site well-suited for wind power, can produce several kilowatt-hours per day. It’s a simple and robust solution for generating your own energy locally without relying on the grid.

Water pumping in rural areas

Where electricity is lacking, the Lenz turbine can be turned into an extremely effective wind-powered water pump. It can drive an irrigation system or supply drinking water from a well or a shallow aquifer. Its small footprint and robust build make it a valuable ally for agriculture and humanitarian aid in windy regions.

Compact installations

Thanks to its compact design and small ground footprint, the Lenz turbine can fit into a wide range of contexts. It can be mounted on the roof of an RV or on a boat to provide mobile power, or find its place in urban or residential areas where space is limited. And since it operates almost silently, it’s perfectly suited for use in inhabited areas.

Field Experience with Lenz Turbines

When I was involved in development aid work in Africa, this wind turbine model proved invaluable on countless occasions. Its biggest strengths are simple fabrication using very common materials and extremely low cost. Thanks to these key advantages, I was able to run fast-track training sessions with the goal of widely promoting this solution in the field, something that would have been far more difficult with other types of wind turbines that are much more technically demanding in many respects.

I also favored the Lenz turbine because it lends itself perfectly to a fully metal construction. And in Africa, you can find skilled artisans almost everywhere, able to work metal with remarkable ingenuity. The only components I had to import were self-lubricating thrust ball bearings for the vertical shaft support and a few neodymium magnets for building the generator. Everything else could be sourced locally, including the materials to make excellent water pumps.

In the beginning, the only real challenge was in electrical generation, because building a suitable low-RPM generator is no easy task. I often used a generator of my own design with a Maglev effect. This meant that when it spins, it creates a magnetic field that slightly lifts the turbine, which significantly reduces friction losses. Even so, and although the electrical output was decent, I measured that the generator was running at only about 40% of its potential capacity. In other words, it was not exactly optimal.

To address this, I focused more on torque and added a small mechanical step-up system: a toothed belt and two pulleys salvaged from motorbikes or old machines. This allowed me to multiply the rotation speed by about 2.5 to 3 times, depending on the parts I had available.

Later, in both Western countries and Asia, I had access to semi-industrial manufacturing processes that allowed me to build excellent prototypes. Even so, no manufacturer was willing to take on the project, probably because I did not communicate enough to clearly demonstrate public interest in this solution. But it’s never too late to do things right, and my schedule is now much more relaxed. So, wait & see. 😉

In both cases, whether in Africa or elsewhere, I can say without hesitation that Lenz turbines have served me extremely well and given me immense satisfaction to build and to watch in action.

Conclusion

In summary, the Lenz turbine is a versatile vertical-axis wind turbine. It can generate electricity or pump water with remarkable efficiency considering its simplicity. For anyone wanting to get into DIY wind power, it’s probably one of the best choices out there.

Whether your goal is to reduce your energy dependence, deepen your understanding of physics, or simply enjoy experimenting, this turbine combines the useful with the enjoyable. Building it is an educational experience, and in an educational or training project, seeing it light up a bulb or pump water provides genuine satisfaction. Few wind turbine models deliver a functional result this easily.

Surprisingly, to my knowledge there are no industrial models based on the Lenz concept. Yet the potential for development is huge. One could easily imagine medium-scale versions (10–20 kW) making use of this principle. Many avenues for optimization remain to be explored: blade profiles, materials, dedicated generators… the field is wide open.

If this wind turbine inspires you, go for it! Start your own project or even a start-up, there’s real potential. And if you need advice, the comments section below is here to help. Don’t hesitate to share your work on the forum too 🙂

I’ve put a lot of time into creating this technical guide. If it’s been useful to you, please take 20 seconds to buy me a coffee (or more) on Buy Me a Coffee. That’s what keeps me awake to create new guides and improve the ones already online. Your support really makes a difference 😉

No chatbot here pretending to know it all. Just real, friendly humans happy to help. Feel free to jump into NovaFlow if you have questions or just want to share your thoughts on this guide.