The Complete Guide to Magnus-Effect Wind Turbines

Magnus-effect wind turbines are among the most intriguing technologies in wind power. Still largely unknown to the general public, they rely on a clever physics principle that transforms rotation into usable lift, which can then be harnessed to generate energy or even to propel vehicles!

Long sidelined compared to classic fixed-blade designs, they are now gaining attention because of their unique aerodynamic behavior and the opportunities they create under favorable conditions.

This guide walks you through how this type of turbine works. We will explore where they make sense, how to deploy them effectively, and why they deserve a role in innovative projects, whether for real-world commercial applications or DIY experiments.

History of the Magnus Effect

Heinrich Gustav Magnus (1802 to 1870) is far more than a name attached to a physics formula. He was a hands-on experimentalist with a long record of sharp discoveries, from gas expansion and gas absorption by blood to water vapor pressure, heat conduction in gases, heat polarization, thermoelectricity, and important studies on electrolysis and induced currents.

In short, Magnus was a complete physicist and chemist. Before him, the idea that a spinning object veers off its path was not unknown. Isaac Newton noticed it in the 17th century while observing game balls. In the 18th century, Benjamin Robins linked it to musket ballistics. Magnus provided the decisive experimental proof in the mid-19th century. Using a rotating cylinder placed in an airstream, he measured and characterized the lateral force. That demonstration sealed the effect’s name. Sources place this experiment around 1852 or 1853.

Later, in the early 20th century, the theory was formally developed by Martin Wilhelm Kutta in 1902 and by Nikolai Zhukovsky in 1906, linking lift to circulation around a profile. At the same time, Ludwig Prandtl introduced the concept of the boundary layer in 1904, explaining how viscous forces keep the flow attached to the surface.

Defining the Magnus Effect

Air is a fluid. Yes, a real fluid like water, just less wet 🙂 Whenever a rotating object interacts with an airstream, it experiences a lateral force. That’s the Magnus effect.

Variables used:

ρ = air density (lb/ft³ or slugs/ft³)

V = relative wind speed (ft/s)

Γ = circulation around the object (ft²/s)

R = cylinder or rotor radius (ft)

ω = angular velocity (rad/s)

L′ = lift per unit length of the cylinder, meaning force per foot of rotor (lbf/ft)

Core formulas:

L′ = ρ V Γ

For a smooth rotating cylinder: Γ ≈ 2 π R² ω

Useful magnitude: L′ ≈ 2 π ρ V R² ω

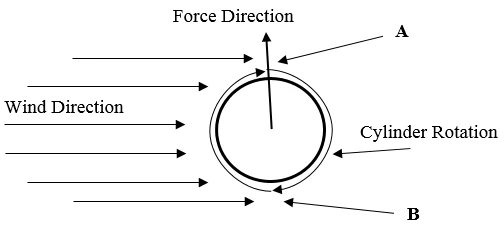

Here is a simple way to visualize it: the wind blows from left to right. The cylinder spins. If the rotation is clockwise, the top moves with the wind, which increases speed and lowers pressure. The bottom moves against the wind, which decreases speed and raises pressure. That difference in pressure creates a lateral force pointing upward. Reverse the rotation (counterclockwise) and the situation flips, so the force points downward instead.

Think soccer or tennis. A curled shot or a topspin makes the ball swerve because a lateral force acts on it during flight. It is not magic. The spin alters the airflow and generates that force. A Magnus wind turbine uses the same principle in a controlled way: we deliberately impose rotation on a cylinder or sail to create the desired force, and then convert it into torque on the shaft to produce electricity.

On the Water: Cousteau, the Turbosail, and Flettner Rotors

Marine applications of the Magnus effect and its variations are among the most spectacular. In the 1920s, German engineer Anton Flettner tested two tall rotating cylinders on his ship, the Buckau. When spinning, these rotors produced lateral lift from the Magnus effect that could propel the vessel. It was the first full-scale demonstration of the principle at sea.

More than sixty years later, Jacques-Yves Cousteau, the famed explorer, filmmaker, and ocean advocate, revived the concept but transformed it into something new: the turbosail.

Important note: contrary to what some poorly researched blog posts claim, a turbosail is only inspired by the Magnus effect. It does not rely on it in the strict sense because there is no spinning cylinder involved. Instead, it is a thick, ovoid sail extended by a movable flap that shapes an intrados and an extrados, exactly like an airplane wing. For efficient operation, the sail must be oriented to the wind just like a conventional sail.

What makes it special is the way Cousteau solved the drag problem. A thick profile would normally cause heavy turbulence on the extrados side. To avoid that, Cousteau integrated internal suction: by drawing air at the right spot, the airflow stays attached to the profile and lift increases dramatically. This is why it is called a suction profile. Cousteau’s emblematic vessel, the Alcyone, launched in 1985, carried two such turbosails. Tests showed fuel savings of more than 30% in favorable conditions, which was impressive for that period.

The story did not end with the Alcyone. Follow-up projects aimed to equip other vessels such as the Calypso II, though they remained on paper. More recently, commercial ships have brought the idea back. In 2020, the Dutch cargo ship Ankie was fitted with two turbosails to reduce fuel consumption.

In summary: a Flettner rotor relies directly on a spinning cylinder to exploit the Magnus effect, while Cousteau’s turbosail is an inspired adaptation that generates lift using a suction-augmented airfoil. Both approaches share the same goal of reducing fossil fuel use and harnessing wind power for propulsion.

Other Applications of the Magnus Effect

Aviation

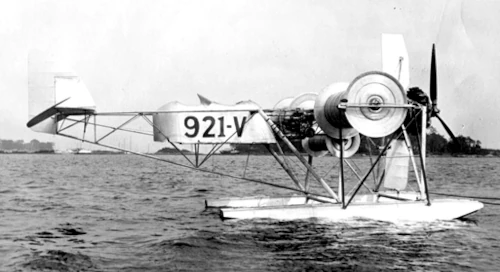

Aviation has explored several ways to use the Magnus effect. In the 1930s, some prototypes replaced wings entirely with rotating cylinders. One of the best known was the Plymouth A-A-2004.

The concept was attractive: generate strong lift at low speed and take off with only a very short run. In practice, these historical “Magnus” aircraft turned out to be heavy, complex, and far less efficient than expected. They remain memorable mostly as educational demonstrators.

More recently, research has shifted toward cyclorotors and cyclocopters. These devices resemble horizontal rotors whose blades rotate fully through 360°. The result is thrust vectoring in any direction with remarkable precision. The Magnus effect contributes to the physics of the blades, working alongside standard aerodynamic principles. The University of Maryland has demonstrated micro-drones capable of very stable hovering with this method. In Austria, CycloTech has built eVTOL demonstrators with cyclorotors that provide full thrust and attitude control, opening the door to aircraft with extreme maneuverability.

Ballistics

Ballistics studies the motion of objects launched into space. It goes far beyond firearms: think weather balloons, satellites, space probes, and high-altitude research vehicles. In this peaceful context, the Magnus effect can help correct or stabilize a trajectory and even provide controlled steering.

However, when it comes to firearms, guns, or missiles, the answer is a firm no. Those are instruments of death that should be in nobody’s hands. On NovaFuture we have zero interest in encouraging or promoting such uses.

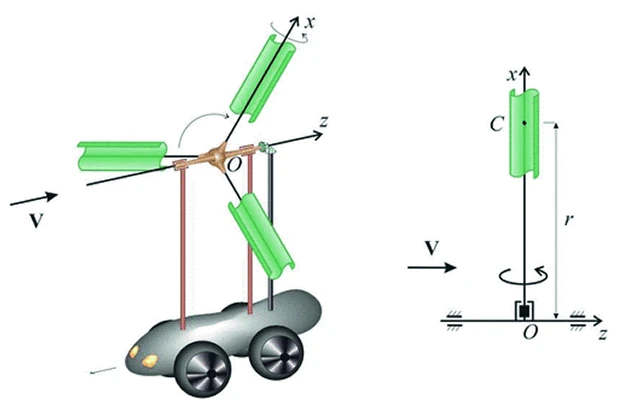

Experimental Ground Vehicles

This is arguably the most playful and accessible way to experiment with the Magnus effect. Imagine a lightweight cart or go-kart equipped with one or two Magnus rotors. By varying rotor spin and orientation, lift can be converted into thrust, allowing the vehicle to move with the wind.

Prototypes already exist, often developed in research labs. In some cases, rotating cylinders are not used for propulsion but instead to generate clean downforce, for example in race-car test setups.

This use of the Magnus effect is a perfect playground for a campus project, a fab lab, or a technical competition. Extra credit if you add sensors to measure performance and use the data to refine your engineering.

What’s Next

Several paths are being studied or developed today:

– Hybrid sail and rotor systems on coastal ships, with tilting rotors that can pass under bridges.

– Cyclorotor drones with extreme maneuverability, capable of hovering, forward flight, and VTOL transitions.

– Airborne wind turbines and Magnus kites, still experimental, designed to capture strong high-altitude winds.

– Ultra-robust Magnus turbines designed for harsh climates, equipped with precise electronic controls to keep generating even during cyclonic conditions.

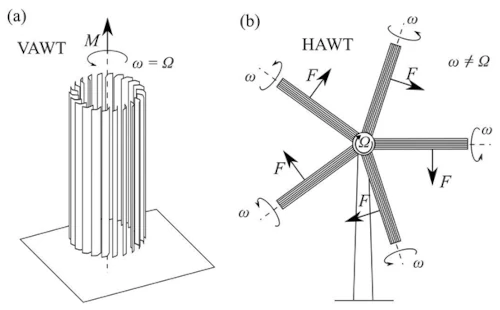

Magnus Wind Turbines: Horizontal-Axis and Vertical-Axis

One distinctive feature of Magnus wind turbines is that they exist in two very different architectures: horizontal-axis and vertical-axis. This is not just a matter of aesthetics. The choice directly affects efficiency, stability, and site integration.

Horizontal-Axis Magnus Turbine

These machines operate much like conventional three-blade turbines. The sails or cylinders are mounted on a rotor that must yaw into the wind, and they spin to generate the required lift. This setup can achieve high efficiency, particularly where winds are steady and laminar. The tradeoff is that precise control of rotation is necessary to avoid losses at low speed or in turbulence. Starting can be more difficult, so a motorized assist at launch is often helpful.

Vertical-Axis Magnus Turbine

In this version, sails or cylinders rotate around a shaft that stands perpendicular to the ground. The main advantage is that it tolerates turbulent winds better and requires no yaw mechanism to face the wind. Its ground footprint is small, which makes it suitable for urban environments. However, it must still be placed high in a well-swept location. Compared to horizontal-axis designs, this is a compromise. Theoretical efficiency is usually somewhat lower, but steadier production in variable conditions can make up for that.

Design Tradeoffs

Horizontal-axis designs aim for maximum performance in good wind conditions. Vertical-axis designs focus on versatility and easier siting. In both cases, the number of sails or cylinders, their profile, and their diameter strongly affect efficiency and cut-in behavior. A well-shaped profile combined with precise electronic control can make the difference between a sluggish prototype and a productive machine.

Design and Build

Building a good Magnus wind turbine is not a quick weekend project. It is arguably the most complex type of wind turbine to construct. Every detail matters: perfect balance, precise electronic control, mechanical strength under gusts, and aerodynamic optimization. It is both a serious technical challenge and an exciting learning journey in machining, electronics, and applied physics. Those who attempt it come away with strong skills and the satisfaction of mastering a very unusual machine.

Hidden Content

A very important part of this how-to guide is not visible. Only members can access the full content. Registration is 100% free and takes just a few seconds. Become a member and enjoy all the services of the site. If you are already registered but still see this message, make sure you are logged in to unlock full access.

Pros and Cons of Magnus-Effect Turbines

Pros

- Resist violent hurricanes.

- Provide high energy production potential in extreme conditions such as cyclones or tropical storms.

- Allow simple and cost-effective sail fabrication.

Cons

- Require higher cut-in wind speeds compared to classic turbines.

- Depend on rigorous electronic control to start and to optimize rotation.

- Peak efficiency relies on active and highly precise regulation.

Bottom line: Magnus-effect wind turbines can be excellent machines, but mainly in specific contexts. They are best suited to coastal areas with strong winds, highly exposed sites prone to cyclones or hurricanes, or elevated locations that capture the true wind. That is why they are often seen as high-flying kites or installed on the rooftops of tall buildings to take advantage of powerful, steady winds.

Bonus Video 🙂

Here is a short and inspiring video of a small Magnus-wing airplane. Everything works smoothly, and the design performs beautifully. Full credit to its builder.

Conclusion and Takeaways

In our view, building a Magnus-effect wind turbine is a golden opportunity for a learning project that accelerates technical creativity. It is an ideal playground for students, makers, and renewable energy enthusiasts, and even a fun way to introduce children to science through small-scale experiments.

Yes, Magnus turbines remain rare. That does not mean they are ineffective. It mostly shows that most designers concentrate on models that are simpler to design and industrialize. Nothing prevents someone from developing a high-performance commercial model. It simply requires serious engineering. With today’s tools and materials, this technology still offers a lot of potential. If it inspires you, why not consider launching a professional project around this alternative?

In any case, if you want advice or if you would like to share your experience on this topic, the comments section below is ready for you 🙂

This guide required a lot of work to prepare. If you would like more in-depth pieces like this, thank you in advance for offering your support with one or more coffees on Buy Me a Coffee. NovaFuture is free and 100% independent, and it only grows thanks to your shares and your generosity.

No chatbot here pretending to know it all. Just real, friendly humans happy to help. Feel free to jump into NovaFlow if you have questions or just want to share your thoughts on this guide.