The Complete Guide to Darrieus-Type Vertical Axis Wind Turbines (VAWT)

The History of the Darrieus Wind Turbine: From Obscurity to Rediscovery

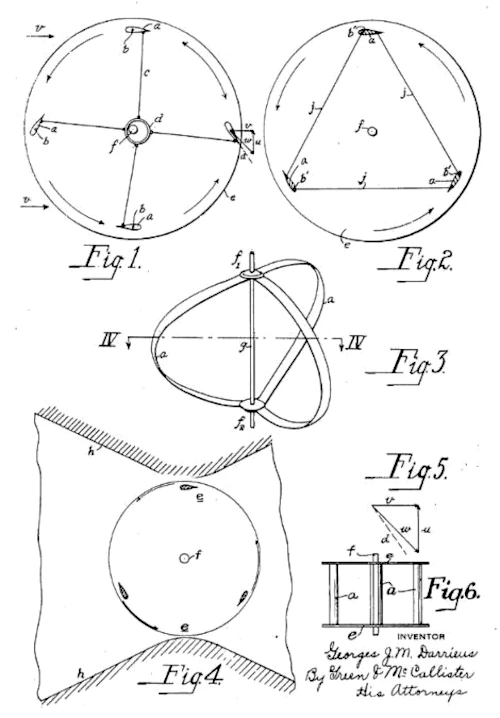

The Darrieus wind turbine, part of what we now call the VAWT family (Vertical Axis Wind Turbines), is named after its inventor: French engineer Georges Jean-Marie Darrieus. In 1931, this visionary filed a patent for a vertical-axis wind turbine capable of spinning through aerodynamic lift, generated by the motion of its blades in the wind. It’s a principle directly inspired by airplane wing profiles, but adapted here to a fixed-axis rotation. Its shape, with two large curved blades joined at both ends, quickly earned it the nickname “eggbeater turbine” because of its striking resemblance to a giant kitchen whisk.

At the time, Darrieus’s invention remained largely theoretical and on the fringes. It was too far ahead of its time and was quickly overshadowed by the rapid development of horizontal-axis wind turbines, which were easier to design for large-scale installations in wide-open rural environments. For decades, the Darrieus concept was pushed to the sidelines of renewable energy history.

Interest started to grow again in the 1980s and 1990s, thanks in part to engineers like Ion Paraschivoiu, who advanced aerodynamic modeling through the Double Multiple Stream Tube (DMST) model, and to new demands such as decentralized energy production, urban integration, and the need to reduce both noise and visual impact. In these more complex environments, vertical-axis turbines, and the Darrieus model in particular, began to prove their worth where conventional rotors struggled.

A second wind came in 1995 with the introduction of the Gorlov helical turbine, originally designed for hydroelectric generation. Its creator, Alexander Gorlov, a professor of Russian origin, built on the Darrieus principle but introduced a helical twist to the blades. The result was smoother rotation, a major drop in vibration, and better dynamic stability overall. This evolution gave the Darrieus concept a new chance to shine in urban settings and in areas with turbulent wind conditions.

Today, as energy autonomy, low-noise operation, and mechanical robustness become key priorities, Darrieus turbines are reclaiming a legitimate place in the transition toolbox. Their story, full of ups and downs, is a perfect example of how forgotten inventions can return to play a meaningful role in building a smarter, leaner, more resilient future.

Understanding the Technical Principle Behind Darrieus-Type Vertical Axis Wind Turbines

Unlike Savonius wind turbines, which rely on drag force to rotate, Darrieus wind turbines harness a far more efficient phenomenon: aerodynamic lift. Borrowed from aeronautics, this principle involves generating a force perpendicular to the apparent wind through the blade’s airfoil shape.

Arranged around a fixed vertical axis, the blades of a Darrieus wind turbine follow a circular path. At every moment, the relative wind (a combination of true wind and rotational speed) strikes the blades at an angle that constantly changes. This is known as the angle of attack. When properly aligned, the blade profile generates lift, which in turn creates torque on the shaft.

In some configurations, this lift can make the rotor spin faster than the actual wind speed. That is a huge advantage over drag-based wind turbines like the Savonius, which quickly reach their limits. That ability allows Darrieus turbines to achieve much higher efficiency, coming close to the theoretical limit defined by Betz’s law. Formulated in 1919, this law states that no wind turbine can extract more than 59.3% of the kinetic energy in the wind. Well-designed Darrieus wind turbines can reach around 40%, while Savonius designs rarely exceed 20%.

But this level of efficiency comes at a cost. The aerodynamic behavior is complex, as the blades alternate between upward and downward motion within the rotation cycle, constantly facing changing airflow conditions.

This leads to phenomena like dynamic stall, where the blade temporarily loses lift before regaining it later. That creates unstable forces and causes significant mechanical wear compared to more conventional blade designs.

To address this, blade geometry and orientation have been gradually improved with techniques like troposkein curvature, helical blade layout, and chord-to-diameter ratio optimization, all aimed at reducing vibration and minimizing energy losses.

Finally, Darrieus wind turbines offer a fundamental advantage: they are independent of wind direction and require no yaw system or pivoting nacelle. This greatly simplifies their mechanical architecture and makes them well suited for turbulent or unpredictable wind environments.

The Different Types of Darrieus Rotors: D-type, H-type, and Helical

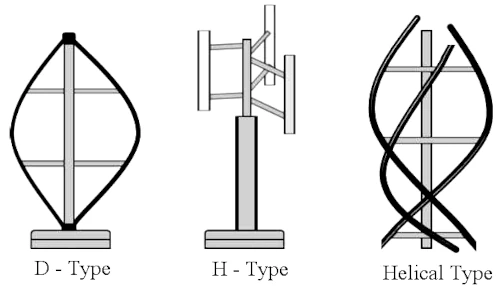

Darrieus-type vertical axis wind turbines (VAWTs) come in three main variants. Each has its own mechanical characteristics, aerodynamic performance, and manufacturing constraints. We are talking here exclusively about lift-based rotors. They all operate on the same fundamental principle but are optimized in different ways depending on the application.

The D-type model is the most iconic. Its two or three curved blades are attached at both ends of a vertical shaft, forming a distinctive silhouette that resembles a giant eggbeater spinning in the wind. This design offers good efficiency and rotational stability, but it also presents mechanical challenges because of the tension on the blade mounts and the need for assisted startup. We’ll explore this point in detail in the next section.

The H-type, on the other hand, is easier to build. It uses straight blades connected by horizontal struts perpendicular to the main shaft. This design simplifies small-scale or DIY manufacturing and allows for better dynamic balancing. It is often chosen for self-built projects or installations with tight space constraints. However, it is slightly less efficient than a well-optimized D-type in terms of theoretical performance.

Finally, the helical model, often associated with Alexander Gorlov, represents the most refined evolution of the Darrieus rotor. In this version, the blades are twisted in a spiral around the vertical axis. This configuration reduces vibration and noise while maintaining more consistent lift throughout the rotation cycle. The helical rotor also offers better resistance to turbulence and extends the lifespan of mechanical components.

According to simulations using tools like QBlade and CFD ANSYS, performance varies slightly among these three variants. The helical rotor shows the highest efficiency (up to 43%), closely followed by the D-type (40%), and then the H-type (around 38%). In terms of noise and stability, the helical rotor again comes out on top, while the H-type wins when it comes to simplicity of construction and maintenance costs.

In short, depending on the nature of the project, one Darrieus design may prove more suitable than another. It is this diversity of approaches that makes the Darrieus concept so appealing. It remains a still underrated but increasingly appreciated solution in the world of vertical wind turbines.

Add a Savonius Rotor or a Starter Motor to Drastically Lower the Cut-In Speed

Some vertical-axis wind turbines (VAWT) of the Darrieus type simply won’t start on their own, or only do so at wind speeds that are rarely reached. Why? Because they rely on aerodynamic lift, which requires a minimum initial speed to kick in. As long as the blades are not turning, there is no lift and therefore no torque. Which means: no motion.

This is especially true for D-type models with curved blades, but it can also affect poorly designed H-type or helical rotors, or those operating in unstable wind conditions.

The most common and efficient solution is to use a small electric motor to kickstart rotation. You might be thinking: Using electricity to power a wind turbine? Isn’t that ridiculous? At first glance, it does sound counterintuitive. But in practice, this technical quirk is negligible. The amount of power consumed is extremely small, just a short impulse to get the rotor moving once the wind is already there.

Some systems use a dedicated starter motor, compact and energy-efficient. Others take it a step further and use the generator itself as a starter motor. In fact, some generators are reversible: just send current through them and they will start spinning. But here is the catch: if you are using an independent motor, you must include a mechanical disconnect system once the rotor is up to speed. Otherwise, the motor stays connected to the shaft, causing friction losses and rapid wear. The best solution is a simple centrifugal clutch, much like the one used in car starters. It engages automatically at low RPMs and disengages completely once the turbine reaches operational speed.

Bottom line for any serious setup: a dedicated starter motor remains the best option. It is more efficient, consumes almost nothing, and is specifically optimized for this task. In contrast, using a generator as a motor is a compromise, less effective and nearly impossible to source for vertical-axis systems. If you are aiming for long-term reliability and top performance, go with the motor.

In both cases, everything is handled automatically: an anemometer detects whether the wind is strong and steady enough to trigger a brief push from the motor. A proper setup ensures it is not reacting to a momentary gust. Once started, the turbine keeps spinning thanks to lift, and when the wind dips, inertia takes over. This energy payback easily compensates for the minimal startup cost.

The downside is that this approach requires precise electronic control, which moves it away from a low-tech philosophy and adds complexity for DIY builders.

That is where an alternative comes in, one that is popular in handcrafted or off-grid projects: integrating a small Savonius rotor into the Darrieus design. Since Savonius rotors rely on drag, they can start spinning on their own, even in light wind. Even better, they generate strong torque right from the first few revolutions, enough to drive the Darrieus rotor until it takes over and accelerates.

This hybrid Savonius–Darrieus configuration runs with no motor, no sensors, no electronics. It is low-tech, durable, and DIY-friendly, which makes it an attractive choice for autonomous setups.

But here is the catch: once the Darrieus is spinning, the Savonius keeps turning slowly. Because its max RPM is low, it ends up acting as an aerodynamic brake. This drag prevents the Darrieus rotor from reaching its full speed and efficiency. The whole point of a Darrieus is to spin faster than the wind, and the Savonius can block that.

If the Savonius rotor is oversized or poorly designed, it can seriously hurt overall performance, to the point of rendering the whole system ineffective. So the key is to design the Savonius as a startup booster only and ensure it becomes as invisible as possible once the Darrieus takes over. In theory, a retractable Savonius rotor would be ideal. But if you are going to add that much complexity, you might as well go back to the starter motor, which is simpler, lighter, and far more effective.

My take? It is a no-brainer. If your goal is to truly harness the exceptional efficiency of a Darrieus, do not weigh it down with a passive brake. An electric start remains the best option by far. Otherwise, you might as well go with a simpler type of rotor, because a Darrieus held back is not just inefficient, it is missing the whole point.

Applications of Darrieus Wind Turbines: Homes, Boats, and Wind-Exposed Sites

Vertical-axis Darrieus wind turbines are not for everyone. Their sleek design, quiet operation, and ability to withstand strong winds make them unique, often used as functional works of art. But let us be clear: when it comes to energy production, they only truly shine under very specific conditions.

For residential use, height is key. A mast of at least 30 feet is essential to avoid ground turbulence and escape the relative wind layer. And even then, it is only viable if the site is well exposed, with strong, steady winds. In other words, this is not for sheltered areas or densely packed urban zones. The cost is high, and maintenance is demanding. So honestly, if your goal is full energy independence, which requires consistent performance, your best bet is a good old horizontal-axis wind turbine. It will be more reliable, far cheaper, technically well-proven, and easier to maintain.

In urban areas, Darrieus turbines do offer a clear advantage: they are indifferent to wind direction. But that alone is not enough to make them a credible alternative to other models that offer the same trait. First, they still need height and clearance. Think rooftops that rise above their neighbors, or exposed flat roofs with minimal obstruction. In those specific cases, they do shine: their resistance to strong wind is far better than traditional HAWTs, and they are incredibly quiet, as long as the blade profiles are well designed. And let us face it, from an architectural point of view, they are gorgeous. In 3D renders, they look amazing. But in real-world conditions, it is a different story. Output tends to be modest. So more often than not, they end up as greenwashing décor rather than a meaningful energy solution. That said, if it helps the skeptics warm up to small wind turbines, why not?

In high-wind zones such as exposed coastlines, storm-prone areas, or even hurricane-risk regions, this is where Darrieus turbines really come into their own. They can take brutal gusts and still deliver, right where conventional models might shut down or fall apart. Thanks to their mechanical stability, they can even be installed at lower heights, provided the surrounding space is wide open. It is a niche, for sure, but in that niche, they are highly effective.

On boats, they sound like a dream: strong, steady winds at sea. But in practice, their bulky blade design makes them less practical than small HAWTs. They are also much more expensive. And do not forget that the model must be specifically built to handle marine environments (sealing, corrosion resistance, etc.). So unless you have a very specific use case or a strong aesthetic vision, it is probably not the most rational option.

Bottom line: a Darrieus wind turbine is for places with strong, steady, unobstructed wind. If your site fits that profile, it can work wonders. If you are prioritizing design or architectural integration, go for it, but make sure to choose a well-performing model. If you are aiming for true 100% energy autonomy, then look elsewhere. Because, as always, there is a big gap between tech fantasies and what actually works on the ground.

Build Your Own Darrieus Wind Turbine: Yes, You Can!

You think a Darrieus looks simple? Two or three blades, a shaft, a generator, done? Bad guess! Behind its minimalist appearance lies a serious level of engineering where no mistake is forgiven. A poor blade profile, imbalance, or bad sizing, and you end up with a kinetic sculpture that makes more noise than electricity. But if you are willing to do things properly, building your own vertical Darrieus-style wind turbine can become a truly exciting project, demanding but deeply rewarding in the end. That is what we are diving into in this section. With the right NovaFuture method, you have got this 😉

Hidden Content

A very important part of this how-to guide is not visible. Only members can access the full content. Registration is 100% free and takes just a few seconds. Become a member and enjoy all the services of the site. If you are already registered but still see this message, make sure you are logged in to unlock full access.

Conclusion: Darrieus Wind Turbines, A Rediscovered Technology Worth Exploring

If you are into wind energy, you simply cannot ignore Darrieus turbines. They are unconventional machines, often misunderstood, but packed with potential on the technical side, the educational side, and even the aesthetic side.

For students, building one (or several) is a fantastic way to strengthen theoretical and technical skills while keeping things hands-on, exciting, and fun. That is why we strongly encourage teachers to bring this kind of meaningful project into the classroom whenever possible.

But here is the thing: you do not need to be in engineering school to give it a shot. There is no age limit or perfect background for learning, experimenting, and growing while doing something useful and rewarding. If you feel up to the challenge, then go for it! Do not be afraid to test things out, mess up, and start over. That is how real progress happens.

And who knows? A project like this might even spark ideas for your future job or business. There is still so much room for innovation in the Darrieus field. And let us be honest, most commercial models out there today are pretty underwhelming. So if someone passionate and focused really dives into it, they could absolutely create a high-performing design that takes off.

In the meantime, we truly hope this guide has been useful to you 🙂 To be honest, it took me quite a bit of time and energy to write, structure, and document it. So if you would like to support the site and help me create more content at this level, it would be awesome if you could take 20 seconds to buy me a coffee (or two) on Buy Me a Coffee. And if you would rather offer another kind of boost, we can talk about it in the comments section below 😉 Either way, thank you for your interest in our work.

No chatbot here pretending to know it all. Just real, friendly humans happy to help. Feel free to jump into NovaFlow if you have questions or just want to share your thoughts on this guide.