Complete Technical Guide to Vertical-Axis Savonius Wind Turbines

In this guide, we’re diving into the world of vertical axis wind turbines, and more specifically the Savonius type, also known as the Savonius rotor. This complete guide will walk you through everything from the history of the design, how and where it can be used, some theory to help you understand how it works, tips if you want to build one yourself, and even what to look for if you’re thinking about buying one. By the end, you’ll know exactly what this tech is all about and whether it could be a good fit for your needs.

History of the Savonius Wind Turbine

The Savonius rotor was invented in 1924 by Finnish engineer Sigurd Savonius, and patented a few years later in 1929. The idea is surprisingly simple: wind pushes into two scoops or “buckets” that are offset from each other, creating a spinning motion. This setup captures the wind’s force through drag, rather than lift like most horizontal turbines.

What makes it special? It’s part of the vertical axis family, which means it’s quiet, starts spinning in low winds, and doesn’t need to face a specific direction. But here’s the real kicker. The Savonius design produces high torque right from the start. That makes it perfect for applications where you need power at low speed, like pumping water or charging batteries slowly but steadily.

Savonius Wind Turbine for Water Pumping

In its original form, the Savonius rotor is highly effective for mechanical water pumping. Its strong torque and low rotation speed make it ideal for driving a pump directly, without necessitating any complex mechanical system or electronic components.

Even better, this type of setup is extremely simple and affordable to build. All you need are a couple of 55-gallon metal drums, a thrust ball bearing, a radial ball bearing for support, and a basic pump. And if you’re into DIY projects, we’ve got a full technical guide to help you build a low-cost wind-powered water pump from scratch.

That said, this configuration isn’t suitable for generating electricity. The rotor turns too slowly. To reach usable speeds for electrical generation, you’d need a speed increaser with gears or a pulley system. But that adds complexity, mechanical losses, and ultimately hurts the efficiency. For electricity, this setup just isn’t the right match.

When it comes to generating electricity, the helical Savonius design is the way to go. In this setup, the bulky scoops are replaced by a sleek, twisted turbine that looks more like a sculpture than a piece of hardware.

This version produces less torque, but it spins much faster. In fact, it spins fast enough to skip the need for a speed increaser altogether. And that’s a big win in terms of simplicity and efficiency.

In the end, it’s hard to say whether this is a renewable energy system or a piece of kinetic art. Maybe it’s both. Either way, it’s proof that technical performance and beautiful design do not have to be opposites. They can go hand in hand.

Savonius for Electric Propulsion

It’s still a niche application, but helical Savonius turbines are actually well-suited for capturing wind power and feeding it into batteries that drive an electric motor connected to a propeller. This setup is perfect for moving a boat.

In this configuration, multiple Savonius rotors are often used, which helps reduce the reliance on large battery banks. After all, out at sea, wind is rarely in short supply. This system can operate in hybrid mode by combining wind with solar panels, or, less ideally, with a backup generator.

One major advantage is that the wind turbines can keep charging the batteries day and night while the boat is at anchor. In the long run, this approach can significantly cut CO₂ emissions from maritime transport, which still relies far too heavily on diesel and other polluting fuels.

Savonius in Advertising Displays

You’ve probably seen those spinning ad signs in front of shops and gas stations. What you might not know is that many of them use a simplified version of the Savonius rotor. The only goal here is to catch the eye of people passing by. That’s it.

Now, I’ve got nothing against clever design, but let’s be honest. If we are going to clutter public space with ads, and it is already way too saturated, we might as well make it useful. Imagine if these spinning signs actually generated clean electricity instead of just visual noise.

If someone wants to dive into that niche, go for it. But personally? The less advertising we see, the better off we all are.

Savonius for Public Lighting

Solar-powered streetlights? Sure, it’s a good start. Cleaner than coal and safer than nuclear. But there’s one big flaw. No sun at night. Which means heavy reliance on batteries. And batteries are expensive, resource-hungry, and far from sustainable.

Now here’s the clever twist. Wind doesn’t stop when the sun goes down. And best of all, the infrastructure is already in place: the streetlight pole. It’s high enough to catch a decent amount of wind, so why not use it? Mounting a Savonius rotor on top is easy, efficient, and doesn’t require any major changes.

Even better, Savonius rotors are built for this kind of setting. They handle chaotic, turbulent wind extremely well, the kind you get in cities. And if placed near highways or major roads, passing trucks can create airflow that spins the turbine even faster. That’s free kinetic energy just waiting to be tapped.

Modern LED streetlights use very little power, so a compact wind turbine can easily cover the need. Add a small solar panel for hybrid reliability, and you’ve got a system that works day and night.

But here’s the real game changer. If production exceeds consumption, which is entirely possible, the surplus energy can be fed back into the grid. So a system that was purely an expense suddenly becomes a source of income. Public lighting, which normally drains city budgets, could actually generate revenue.

So yes, there’s a real startup idea hiding here. Smart cities, lower bills, reduced emissions, and lighting powered by the wind itself. All we need is someone to make it happen.

Roof Ventilation and the Flettner Vent: When Savonius Inspires Fresh Air

Anton Flettner: From Wind Power to Airflow

Anton Flettner was a brilliant German engineer who worked in the early 20th century and collaborated with none other than Sigurd Savonius. While Savonius was focusing on drag-based vertical axis turbines, Flettner was exploring how wind could be harnessed not only for propulsion but also for ventilation and air circulation.

He’s also famous for the Flettner rotor, a cylindrical spinning sail that uses the Magnus effect to propel ships. But that’s another story, and we’ll get into it in a dedicated guide soon.

What matters here is that Anton Flettner took inspiration from the Savonius rotor and applied it to something very practical: ventilation.

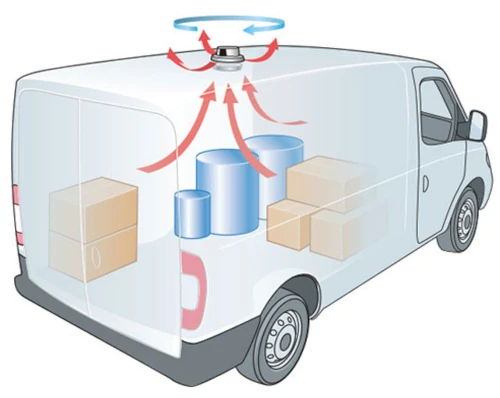

The Flettner Vent: Passive Cooling, No Electronics

The Flettner ventilator, or Flettner roof vent, is a simple yet genius device. It uses a vertical-axis rotor very similar to the Savonius profile, but instead of generating electricity, it’s designed to move air. As wind passes over the rotating vent, it creates a low-pressure zone inside, pulling hot air out from the space below, such as the interior of a van, a truck, a boat, or even a house.

This setup is completely passive. No wires, no batteries, no electronics. Just the wind doing its thing.

And the result? Interior temperatures can drop by 18 to 27°F (or more, depending on the context) without using any air conditioning. That’s energy saving, comfort boosting, and maintenance free, all in one go. On a hot summer day, a Flettner ventilator on the roof of a van can mean the difference between a mobile sauna and a livable space.

It’s also used in buildings for roof ventilation. By constantly extracting warm, stale, or humid air, it improves indoor air quality and reduces the risk of mold, all without a single kilowatt consumed.

A Bit of Low-Tech Magic

The Flettner vent is a perfect example of low-tech that works. Durable, weatherproof, and often made of aluminum or UV-resistant plastic, it’s been used for decades in harsh conditions, including on cargo ships and remote cabins.

It’s quiet, self-regulating, and doesn’t require any maintenance apart from the occasional cleaning. And unlike powered fans, it works day and night as long as there’s a breeze.

What Else?

- It’s 100% compatible with sustainable architecture and passive house principles

- It reduces heat buildup in parked vehicles, especially for delivery vans, campervans, and mobile workshops

- It improves air exchange in attics and warehouses

- It avoids the overheating of parked trucks and buses

- It’s completely autonomous, making it ideal for remote areas and off-grid use

In short, Anton Flettner may have started with wind propulsion, but his contribution to passive ventilation is still going strong and remains deeply relevant today.

Theoretical Operation of a Savonius Wind Turbine

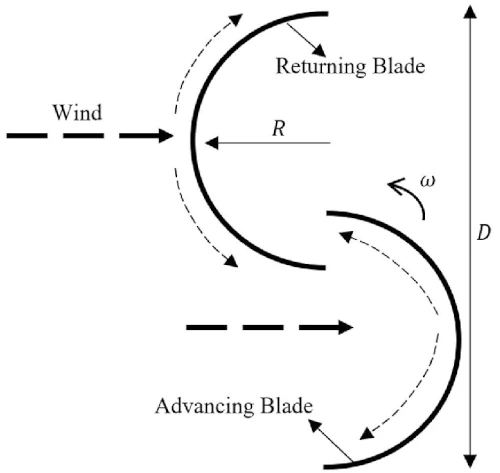

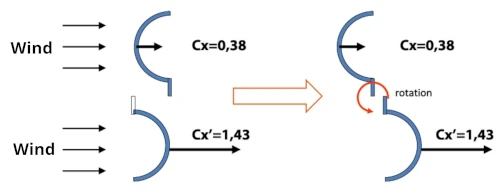

The Savonius wind turbine works on the principle of differential drag. The convex side of the blade offers less resistance to the wind than the concave side. This difference in drag force creates a torque, which causes the rotor to spin.

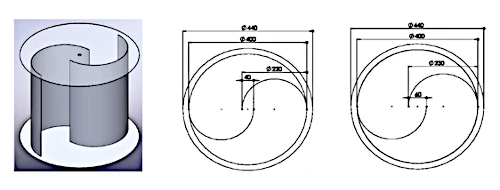

A small gap between the two semi-cylindrical blades allows air to pass through and reduces resistance on the return side. This improves rotational fluidity and increases the overall efficiency. For best performance, the ideal spacing between the blades is around one-sixth of the turbine’s diameter.

The diagram below illustrates the principle of differential drag. The wind applies a drag force defined by the equation:

Fx = 0.5 × Cx × ρ × S × V²

This diagram helps explain how asymmetric forces drive the rotor. However, it only accounts for local aerodynamic forces and not for the overall energy output.

To estimate the theoretical power a Savonius turbine might extract, designers often use the generic wind power formula:

P = 0.5 × Cp × ρ × A × V³

But let’s be clear. This is a general formula that applies to any wind turbine. It assumes ideal conditions and does not factor in the detailed geometry of a helical Savonius rotor, which introduces complex airflow behavior.

In practice, calculating the actual efficiency of a helical Savonius turbine is extremely difficult without detailed 3D modeling. Accurate results require simulation in CAD software such as Creo (formerly Pro/ENGINEER) or AutoCAD, often combined with CFD analysis (Computational Fluid Dynamics). Only then can you predict how design variations, like blade twist, overlap ratio, or height, affect performance.

In short, the math gets complicated very quickly. But the physics remains beautifully simple.

Building a Vertical-Axis Savonius Wind Turbine for Power Generation

In this 100% hands-on section, we’ll focus exclusively on a vertical-axis wind turbine built to generate electricity. If you’re more interested in pumping systems, you’ll find everything you need in the dedicated section.

Hidden Content

A very important part of this how-to guide is not visible. Only members can access the full content. Registration is 100% free and takes just a few seconds. Become a member and enjoy all the services of the site. If you are already registered but still see this message, make sure you are logged in to unlock full access.

In Conclusion

I hope this guide sparked your interest in exploring vertical-axis wind turbines, especially the Savonius type. And even more, I hope it inspired you to build one yourself. We’d be thrilled to see photos or even videos of your project! In the meantime, if you need technical advice, feel free to use the comment section a bit further down the page.

This guide is the result of many years of experience, and I’ve spent quite a few hours putting it all together. So if you feel like offering me a coffee on Buy Me a Coffee, I’d really appreciate it 🙂 It helps keep me sharp and caffeinated so I can keep making new guides!

No chatbot here pretending to know it all. Just real, friendly humans happy to help. Feel free to jump into NovaFlow if you have questions or just want to share your thoughts on this guide.